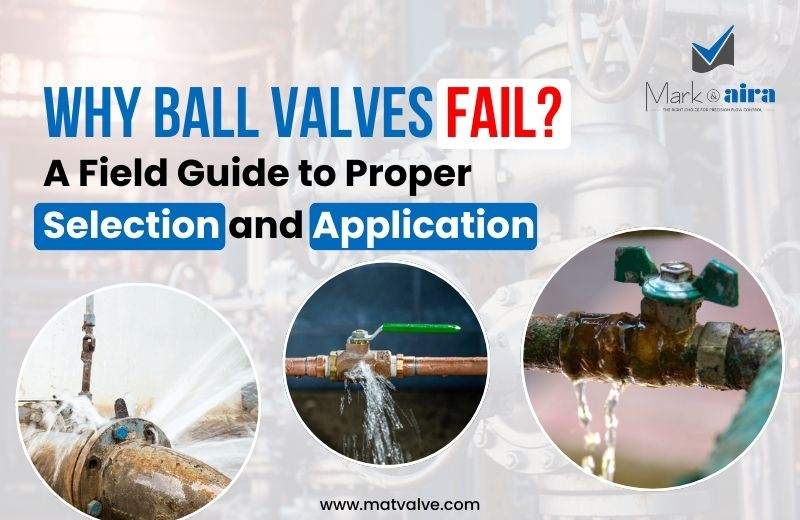

If you walk through any oil refinery, water treatment plant, or even look under your kitchen sink, you’re going to find a ball valve. They are the “reliable old friend” of the piping world. But in an industrial setting, “reliable” only happens if you pick the right design for the specific pressure and media you’re moving.

I’ve seen plenty of projects hit a wall because someone grabbed a standard floating ball valve for a high-pressure line that really needed a trunnion-mounted ball valve. It’s a small detail that leads to a massive headache. This guide is here to make sure that doesn’t happen to you.

What Is a Ball Valve?

At its core, a ball valve is a shut-off valve that controls the flow of a liquid or gas by means of a rotary ball having a bore. You turn the handle 90 degrees, the hole aligns with the pipe, and fluid flows. Turn it back, and the solid side of the ball blocks the flow.

It’s simple, fast, and provides a great seal. Because they close so quickly, they are perfect for emergency shut-offs. However, you have to be careful—closing a valve too fast in a high-velocity line can cause a “water hammer” which sounds like a sledgehammer hitting your pipes and can do just as much damage.

Types of Ball Valves

Not all ball valves are built the same. The way the ball is held inside the body changes how much pressure it can handle and how long it will last.

1. Floating Ball Valves

In this design, the ball isn’t fixed to anything at the bottom. It “floats” between two seats. When the valve is closed, the upstream pressure actually pushes the ball against the downstream seat. This creates a very tight seal.

- Best for: Small to medium sizes and lower pressure systems.

- The Catch: At very high pressures, the ball pushes so hard against the seat that it becomes difficult to turn the handle.

2. Trunnion Mounted Ball Valves

For the heavy-duty stuff, you need a trunnion. Here, the ball is supported by a shaft at the top and the bottom (the trunnion). The ball doesn’t move; instead, the seats are spring-loaded and press against the ball.

- Best for: Large diameters (over 6 inches) and high-pressure applications.

- The Catch: They are more expensive and have a more complex internal design, but they won’t seize up under load like a floating ball might.

3. Full Bore vs. Reduced Bore

This is a choice about flow efficiency.

- Full Bore Ball Valve: The hole in the ball is the same size as the pipe. There’s zero resistance to flow. If you need to “pig” your lines (clean them with a mechanical plug), you need full bore.

- Reduced Bore Ball Valve: The hole is smaller than the pipe diameter. It’s cheaper and lighter, but it creates a bit of a pressure drop. For most standard water or air lines, a reduced bore is perfectly fine and saves you money.

Applications Across Industries

Because they are so versatile, industrial ball valves show up everywhere.

- Oil & Gas: They are the gold standard for main process lines because they can handle crude oil and gas without leaking.

- Water Treatment: Used in filtration systems and chemical dosing.

- Chemical Processing: When dealing with corrosive acids, ball valves made of specialized alloys (like Hastelloy) provide the safety needed.

- Power Plants: Used in cooling water loops and low-pressure steam lines.

Advantages & Limitations

Let’s be honest—nothing is perfect.

Advantages:

- Speed: 90-degree turn is much faster than spinning a gate valve wheel ten times.

- Reliability: They hold a seal even after years of use.

- Compact: They generally take up less vertical space than globe or gate valves.

Limitations:

- Throttling: Don’t use a ball valve to “regulate” flow (keeping it half-open). The high-velocity fluid will erode the seats, and soon the valve won’t seal properly when you actually need it closed. If you need flow control, you should be looking at flow control valves instead.

- Trapped Volume: When the valve is closed, a tiny bit of fluid is trapped inside the ball. If that fluid expands (like water freezing), it can actually crack the valve body.

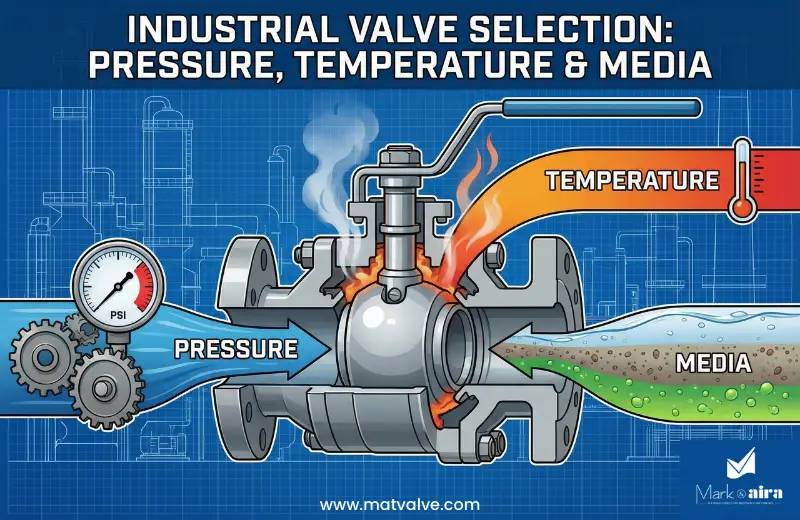

Selecting the Right Ball Valve

When you’re looking at a catalog, don’t just look at the price. You need to verify a few technical specs:

- Body Material: Carbon steel is standard, but if you’re near the coast in the UAE, you likely need 316 Stainless Steel to fight off corrosion.

- Seat Material: Soft seats (PTFE/Teflon) are great for a perfect seal but fail at high temperatures. Metal seats are tougher but might allow a tiny “micro-leak.”

- End Connections: Do you need flanged, threaded, or socket weld? This usually depends on your existing piping standards.

- Pressure Rating: Check the PN or ANSI class. A Class 150 valve in a Class 300 system is a recipe for a disaster.

For more on the technical side, read our deep dive on industrial valve selection parameters.

Read here;

Common Mistakes to Avoid

We have seen a lot of money wasted on the wrong hardware. Here are the top three blunders:

- Using the wrong seal for the media: Using a standard seal for a slurry line. The grit gets into the seat and tears it up the first time you turn the handle.

- Ignoring the “Fire-Safe” requirement: In oil and gas, you need valves that will still seal even if the soft seats melt during a fire. If you skip the fire-safe certification, you won’t pass inspection.

- Poor Actuation Sizing: If you’re adding a pneumatic actuator, make sure it has enough “break torque” to move the valve after it has been sitting closed for six months. A weak actuator is a paperweight.

A ball valve is a simple piece of tech, but it’s the backbone of your process. Choosing between floating or trunnion, or full bore versus reduced, can be the difference between a system that lasts ten years and one that fails in ten months.

At Mark & Aira Valves, we’ve spent years helping engineers in the UAE navigate these choices. We stock a wide range of ball valve types and applications to ensure you get the right pressure rating for your specific environment.

Not sure which ball valve fits your pipeline? Please contact our technical team for a specification review.