Valves for Decarbonization Industry: Enhancing Efficiency and Sustainability

Introduction

In this blog, we discuss our range of valves for decarbonization industry, and explore how our gate, globe, check, ball, butterfly, plug, and knife edge gate valves are integral to decarbonization projects and how they enhance process efficiency.

As global industries push toward net-zero emissions, valves for decarbonization industry are becoming critical components in achieving energy transition goals. From carbon capture systems to green hydrogen and biofuel facilities, these valves play a central role in ensuring operational safety, efficiency, and regulatory compliance. Therefore, our advanced valve solutions play a critical role in optimizing operations, reducing emissions, and ensuring long-term sustainability in the decarbonization industry.

Why Valves for Decarbonization Industry Are Critical in Achieving Net-Zero Goals

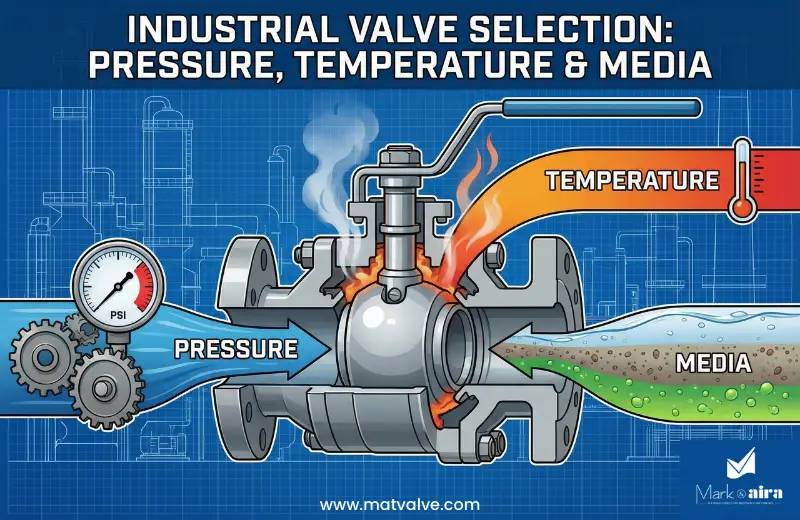

Industrial valves for decarbonization industry applications are essential components in the flow control systems, ensuring efficient regulation of gases and liquids across various decarbonization technologies. Specifically, high-performance valves provide:

- Precise flow control, ensuring minimal energy loss.

- Leak-proof sealing, critical for handling CO₂ and hydrogen safely.

- Corrosion resistance, for handling aggressive fluids and extreme temperatures.

- Long-term durability, reducing maintenance costs and downtime.

Therefore, valves act as gatekeepers, ensuring safety, efficiency, and sustainability across carbon capture, hydrogen storage, and biofuel production processes.

Key Decarbonization Sectors That Rely on Valves for Decarbonization Industry

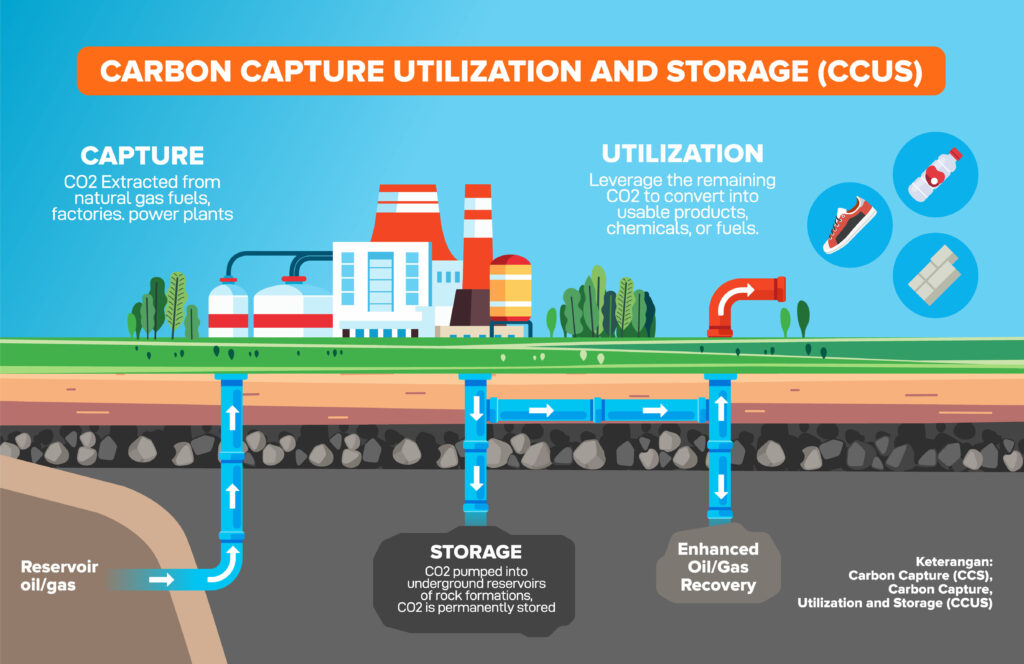

1. Carbon Capture, Utilization, and Storage (CCUS) with Valves for Decarbonization Industry

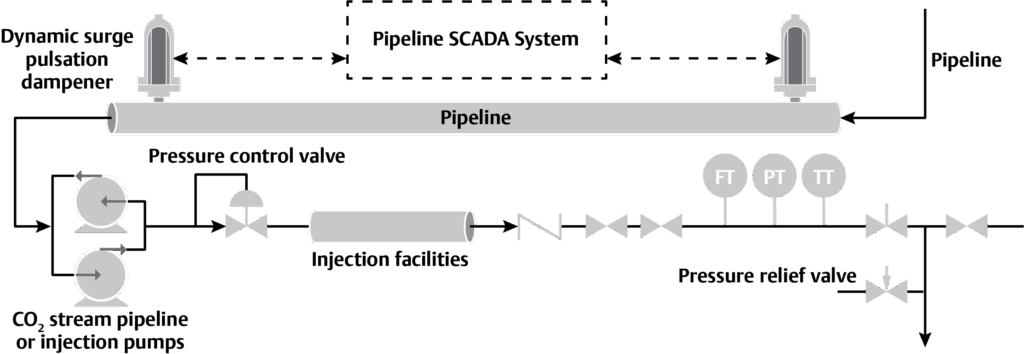

Carbon Capture, Utilization, and Storage (CCUS) plays a vital role in reducing industrial carbon footprints. Consequently, our valves ensure safe and efficient CO₂ transportation and storage by:

Valve Applications:

- Gate and Globe Valves: Used for high-pressure CO₂ injection into storage reservoirs.

- Check Valves: Prevent backflow and ensure continuous CO₂ flow.

- Ball and Butterfly Valves: Optimize flow regulation in pipelines carrying captured CO₂.

2. Hydrogen Production and Storage Supported by Valves for Decarbonization Industry

Hydrogen is a key player in the energy transition, and safe, reliable valve technology is essential. As a result, our high-performance valves ensure:

Valve Applications:

- Plug and Globe Valves: Precise control of hydrogen in electrolyzers.

- Ball Valves: Leak-proof flow management for hydrogen transport and storage.

- Check Valves: Prevent reverse flow and system damage in hydrogen pipelines.

3. Renewable Energy and Biofuels Utilizing Valves for Decarbonization Industry

Valves are crucial in the production of biofuels and biomass energy by managing steam, fuel, and chemical flows. Accordingly, our solutions include:

Valve Applications:

- Knife Edge Gate Valves: Designed for slurry and solid biomass processing.

- Ball and Butterfly Valves: Optimize fuel and steam flow in biofuel reactors.

- Plug Valves: Handle corrosive and high-temperature biofuel processes.

Our Valve Solutions for Decarbonization Industry: Features and Benefits

Gate Valves

- Ideal for high-pressure applications.

- Used in CO₂ injection wells and hydrogen pipelines.

Globe Valves

- Offer precise flow control and throttling capabilities.

- Used in hydrogen electrolyzers and carbon capture plants.

Check Valves

- Prevent backflow and system damage.

- Critical for CO₂ pipelines and hydrogen storage systems.

Ball Valves

- Provide tight shutoff and leak-proof performance.

- Used in biofuels, carbon capture, and hydrogen transport.

Butterfly Valves

- Lightweight and cost-effective for large pipeline applications.

- Ensure smooth operation in CO₂ transport and biofuel plants.

Plug Valves

- Handle high-temperature and corrosive media.

- Essential for biofuel production and hydrogen storage.

Knife Edge Gate Valves

- Designed for handling slurries, biomass, and solid particles.

- Widely used in biomass energy and biofuel plants.

How Valves for Decarbonization Industry Improve Efficiency and Reduce Emissions

Our high-performance valves contribute to decarbonization efforts by:

- Reducing leaks and emissions with superior sealing technology.

- Withstanding extreme conditions in carbon capture and hydrogen storage.

- Enhancing automation and control with smart valve technologies.

- Minimizing energy losses in renewable energy applications.

Moreover, these features ensure long-term value and reliability in demanding industrial environments. Not only that, but they also improve environmental compliance and operational performance.

Why Choose Our Valves for Decarbonization Industry Projects?

- Industry-leading quality: Manufactured with high-precision materials.

- Customizable solutions: Tailored to specific industry needs.

- Global compliance: Meeting safety and environmental regulations.

- Proven track record: Trusted by industries worldwide in decarbonization projects.

In addition, we continuously innovate to provide the most efficient valve technologies available. Therefore, your operations benefit from robust, future-ready flow control solutions.

Conclusion: The Importance of Valves for Decarbonization Industry

Industrial valves are the backbone of decarbonization technologies, ensuring safe and efficient flow control in carbon capture, hydrogen storage, and biofuel production. Hence, our high-performance gate, globe, check, ball, butterfly, plug, and knife edge gate valves provide the reliability, durability, and efficiency needed for industrial sustainability.

Looking for the right valve solutions for your decarbonization project? Contact us today to explore our range of high-performance valves designed to meet the challenges of the evolving energy landscape.

FAQs About Valves for Decarbonization Industry

1. How do industrial valves help in carbon capture?

Valves regulate CO₂ flow and pressure, ensuring safe and efficient carbon capture, transportation, and storage.

2. Which valves are best for hydrogen energy projects?

Globe, plug, and check valves provide precise flow control and leak prevention in hydrogen production and storage.

3. Why are knife edge gate valves used in biofuel processing?

Knife edge gate valves handle biomass and slurry, ensuring smooth processing in biofuel production.

4. What makes our valves ideal for decarbonization applications?

Our valves offer superior sealing, corrosion resistance, and automation compatibility, ensuring efficiency in decarbonization projects.

5. How can I select the right valve for my decarbonization project?

Contact our team for expert guidance on selecting the most suitable valves for your specific industrial applications.