Industrial plants change fast, and so do the demands on equipment. Many industries now choose non-metallic valves over traditional metal ones because the operating conditions keep getting tougher—more chemicals, more aggressive media, and tighter hygiene rules. You see this shift everywhere: in water and wastewater treatment, chemical dosing systems, pharma plants, irrigation networks, and food-grade applications.

These sectors look for corrosion-free performance, easy handling, and long operational life without constant fixes. That’s where non-metallic valves like UPVC, CPVC, PP, PPH, PVDF, PTFE, PFA, and FEP fit perfectly. They handle chemicals better, they don’t rust, and they come with lower lifetime costs.

In this guide, I explain the types, materials, applications, advantages, limitations, and selection points. Think of it as a practical map for engineers, buyers, and plant managers who want reliable, chemistry-friendly valve solutions.

What Are Non-Metallic Valves?

Non-metallic valves are industrial valves made from polymers, thermoplastics, or composite materials instead of metal. They feel lighter, resist corrosion naturally, and perform well in environments where metal valves fail slowly—especially with acids, alkalis, and aggressive chemicals.

They shine in places where purity matters. For example, pharma plants trust PVDF valves because they don’t contaminate fluids. Irrigation systems prefer UPVC because it handles outdoor exposure and water chemistry without reacting.

Some people think plastic valves are always weak. Not true. As a leading Industrial Valve manufacturer, it’s our job to spread awareness about Modern non-metal valves that handle respectable temperatures and pressures as long as you pick the right material. The key is understanding the media and operating conditions.

Types of Non-Metallic Valve Materials

Each material behaves differently. Here’s a clear, engineer-friendly breakdown.

UPVC (Unplasticized Polyvinyl Chloride)

UPVC handles cold water, light chemicals, and moderate pressure. It works great in irrigation lines, RO plants, and general water systems. Temperature range usually stays under 60°C.

CPVC (Chlorinated Polyvinyl Chloride)

When the temperature goes a little higher, CPVC steps in. It works well in hot water pipelines, chemical transfer, and chlorinated water systems.

PP / PPH (Polypropylene / High-Purity Polypropylene)

PP resists many acids and chemicals. You see it in chemical processing units, dosing systems, and wastewater treatment. It also handles abrasion better than UPVC or CPVC.

PVDF (Polyvinylidene Fluoride)

PVDF is the “premium-grade” option for harsh chemicals and high-purity requirements. It handles high temperature and strong acids. Pharma, chemical, and semiconductor industries rely on PVDF valves for critical applications.

PTFE, PFA, FEP (Fluoropolymer Materials)

These materials offer extreme chemical resistance. They work where nothing else survives. Designers use them for linings, coatings, or full-body valves depending on the need.

Glass-Filled & Composite Materials

These options boost mechanical strength without losing chemical resistance. They suit pumping systems and high-demand chemical processes.

Lined valves combine the strength of metal with the chemical compatibility of polymers. Full-plastic valves are lighter and ideal when corrosion is the main enemy.

Types of Non-Metallic Valves

Non-metal valves come in the same functional designs you already know. The difference is in the material performance.

- Ball Valves: Best for on/off control with clean or mildly abrasive media.

- Butterfly Valves: Lightweight and efficient for large pipelines.

- Diaphragm Valves: Perfect for dosing, slurry, and hygienic operations.

- Check Valves: Keep reverse flow under control in water and chemical lines.

- Foot Valves: Used in pumps and suction pipelines.

- Solenoid-Operated Plastic Valves: Ideal for automated dosing lines.

- Actuator-Mounted Polymer Valves: Where industries want automation without corrosion issues.

If you run water treatment plants, RO units, chemical dosing systems, or irrigation blocks, these categories cover almost everything.

Advantages of Non-Metallic Valves

Non-metallic valves bring a long list of practical advantages:

- Superior corrosion resistance: They never rust, even with strong acids or chlorinated water.

- Lightweight design: Installation becomes easier, and stress on pipelines drops.

- Low maintenance: No scaling, rusting, or chemical reaction.

- Better cost across the lifecycle: Less failure, fewer replacements.

- Hygienic: Perfect for pharma, biotech, and food-grade lines.

- Strong chemical resistance: Materials like PVDF and PTFE survive where metal valves die early.

- Economical for large irrigation and wastewater systems: Lower cost with stable performance.

Industries love them because they solve problems that metal valves just cannot ignore.

Limitations of Non-Metallic Valves

Even the best plastic valve has its limits. And it’s better to know them early.

- Temperature limits: Most plastics stay under 60–120°C depending on grade.

- Mechanical stress: They don’t like heavy impact or pipe misalignment.

- High-pressure restrictions: Extreme pressure systems still need metal.

- Abrasive media: Sharp particles wear polymer surfaces faster.

- Permeation: Fluoropolymers resist chemicals, but some solvents can diffuse slightly.

Understanding these limits helps you choose correctly. For high-pressure steam or heavy-duty slurry, you still need metal or lined-metal valves.

Industry-Wise Applications

You find non-metallic valves in almost every modern plant now.

- Water & Wastewater Treatment

UPVC, PP, and PVDF valves handle chemical dosing, sludge control, chlorine lines, and treatment cycles. - Chemical Dosing & Transfer

PP and PVDF shine here thanks to chemical resistance. - Pharma & Biotech

PVDF and PTFE valves maintain purity and hygiene. - Food & Beverage

No rusting, no contamination—perfect for CIP wash and transfer lines. - Irrigation

UPVC valves dominate because they are cost-effective and durable outdoors. - HVAC Systems

CPVC and PP valves find use in hot and cold water controls. - Desalination & RO Plants

UPVC and PVDF handle the full water-treatment chain smoothly.

Also Read,

How to Select the Right Non-Metallic Valve

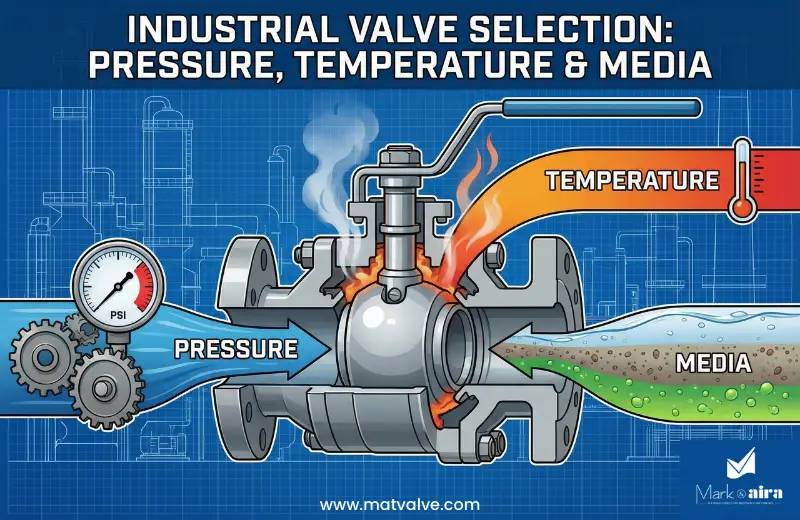

Engineers choose valves based on a few critical points:

- Media type: Acidic, alkaline, chlorinated, or abrasive.

- Temperature & pressure: Stay within material ratings.

- Flow conditions: Ball or butterfly depending on line size.

- Chemical compatibility: Key for dosing and chemical-transfer lines.

- Certifications: NSF, FDA, USP Class VI, ISO for hygiene-sensitive segments.

- Actuation compatibility: Manual, solenoid, pneumatic, or electric actuator.

Non-Metal Valves + Automation

Automation grows fast in water treatment, irrigation, and chemical processing. They all need reliable valve control.

- Pneumatic actuator setups work well in dosing systems.

- Electric actuators pair nicely with UPVC or PP valves for remote control.

- Solenoid-operated polymer valves help in precise chemical injection.

- Smart monitoring systems now plug into polymer valve assemblies for real-time control.

Automation turns polymer valves into intelligent flow systems, not just manual units.

Maintenance Guide & Best Practices

Good maintenance makes these valves last surprisingly long.

- Follow a simple installation checklist. Don’t overtighten.

- Inspect seals and O-rings periodically.

Clean the valve body when media carries suspended solids. - Avoid stretching or misaligning the pipe.

- Use proper supports so the valve doesn’t take the pipeline weight.

Small steps here save a lot of downtime later.

Real-World Industry Case Examples

Here are quick snapshots from real installations:

- A wastewater treatment unit replaced corroded metal valves with PP valves and reduced failures by almost 70%.

- A pharma plant shifted to PVDF valves to avoid product contamination and gained better process validation.

- A large irrigation network installed UPVC valves because they handle water chemistry changes and last longer.

These cases repeat everywhere. Once industries switch, they rarely go back.

Comparison: Metallic vs Non-Metallic Valves

Let’s keep it simple.

- Performance: Plastics win against chemicals; metals win against heat and pressure.

- Cost: Plastics cost less to install and maintain.

- Service life: Plastics beat metals in corrosive environments.

- Maintenance: Plastics stay cleaner; metals need coatings and checks.

- Installation effort: Plastics are far lighter and easier to handle.

Engineers now mix both categories depending on the line conditions.

Buyer’s Checklist

Before finalizing, tick these points:

- Correct material selection

- Specification sheet verified

- Certifications checked

- Pressure & temperature rating within limit

- Right end connection type

- Actuator compatibility

- Brand warranty

A disciplined selection avoids 90% of valve failures.

If you want corrosion-free, low-maintenance, and long-life performance, explore our complete range of Non-Metallic Industrial Ball Valves.

From UPVC to PVDF and advanced fluoropolymer solutions, we guide you to the right product based on your application.

Browse our product categories or speak with our technical team for recommendations.