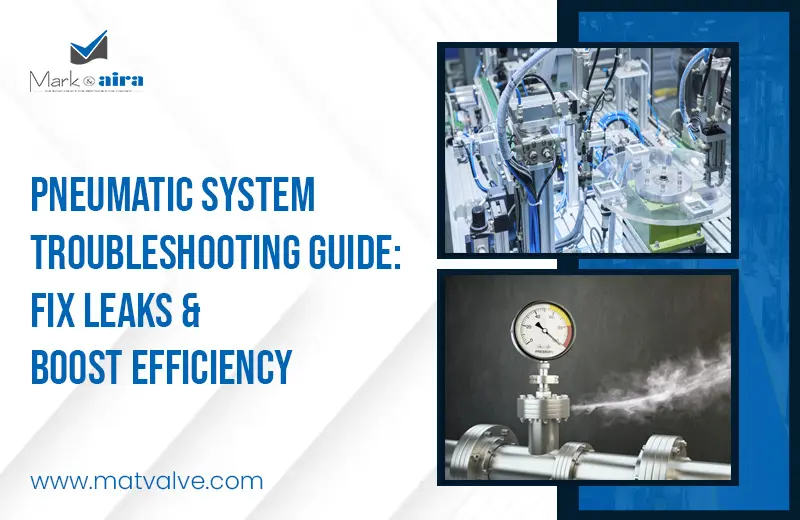

In any industrial setting, a pneumatic system is the heartbeat of production. When it runs smoothly, your automation is seamless. But when a pneumatic cylinder begins to stutter, or a leak starts hissing, the resulting downtime can cost thousands in lost productivity and energy waste.

If you are facing pressure drops or erratic machine behavior, you don’t always need a full system overhaul. Most issues can be traced back to a few key components. In this guide, we will walk through the expert steps to troubleshoot your pneumatic system and get your operations back on track.

1. Identifying the "Silent Killer": Air Leaks

Air leaks are the most common cause of pneumatic system failure. Not only do they force your compressor to work harder (increasing energy bills), but they also lead to significant pressure drops that affect tool performance.

- The Soap Water Test: If you hear a hissing sound but can’t find the source, spray a mixture of soap and water on fittings, joints, and seals. Bubbles will form exactly where the air is escaping.

- Check the Tubing: Look for cracks or brittle sections in your pneumatic hoses. Often, a quick replacement of a pneumatic fitting is all it takes to restore pressure.

2. Solving Jerky or Slow Pneumatic Cylinder Movement

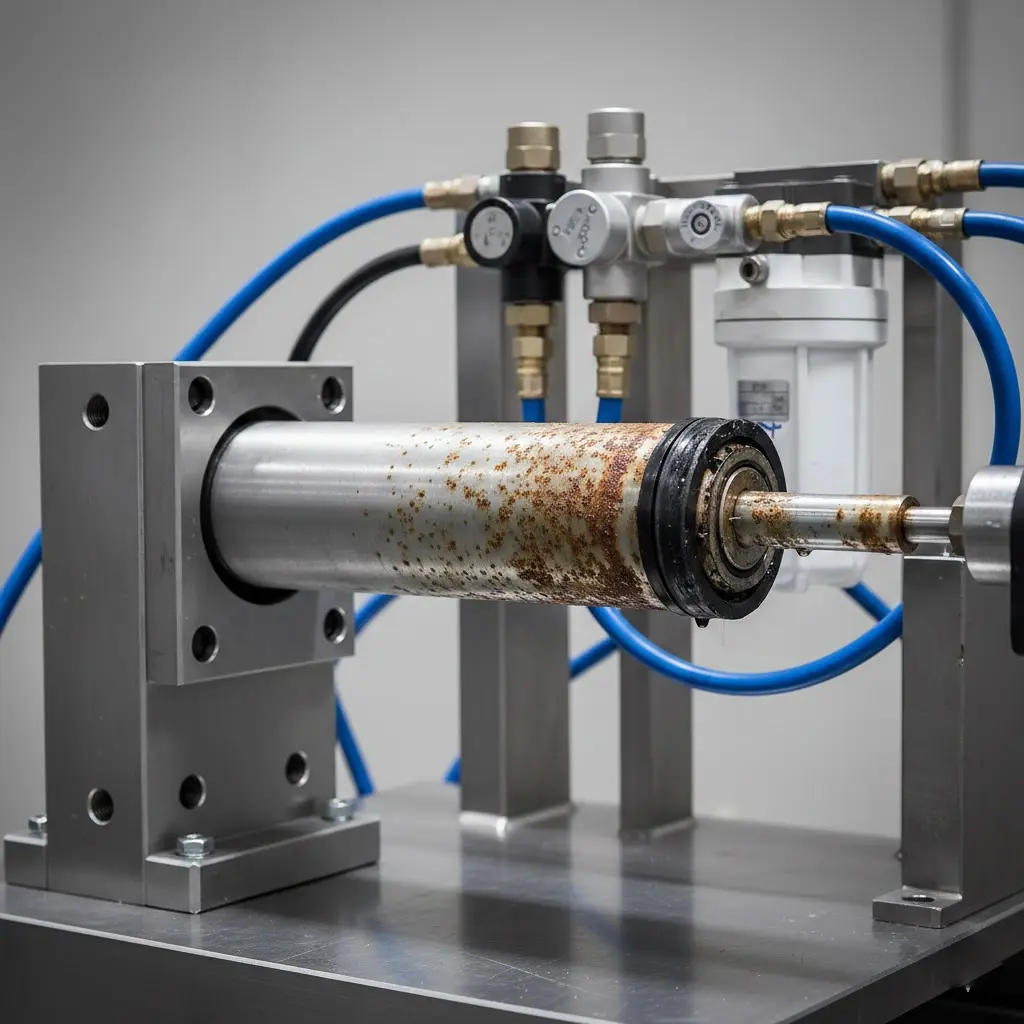

If your pneumatic cylinders are moving inconsistently or failing to reach full stroke, the issue is usually mechanical resistance or internal bypass.

- Inspect the Seals: Worn internal seals allow air to bypass the piston, causing a loss of force. If the cylinder “creeps” or moves slowly under load, it’s time for a seal kit or a new ANC Square or Round Body Cylinder.

- Check for Misalignment: Ensure the cylinder rod is not binding against the load. Misalignment is a leading cause of premature seal failure.

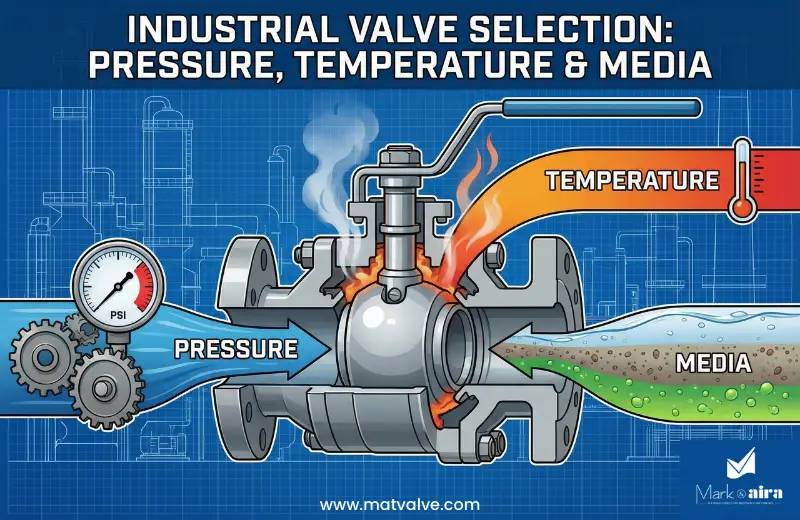

3. The Vital Role of FRL Units: Filter Regulator Lubricator

Contaminated air is the number one enemy of pneumatic components. Dust, moisture, and oil can clog valves and corrode cylinders from the inside out.

- The Filter: Is your air filter clogged? A dirty filter element causes a massive “pressure differential,” meaning your compressor is pushing 7 bar, but your machine is only receiving 4 bar.

- The Lubricator: Without proper lubrication, the friction in your valves and cylinders will cause them to overheat and fail.

- The Solution: Regularly drain your moisture separators and ensure your FRL Units are topped up with the correct pneumatic oil.

4. Troubleshooting Solenoid & Directional Control Valves

When a pneumatic system fails to “shift” or cycle, the problem usually lies in the control valves.

- Check the Coil: Use a multimeter to ensure the solenoid coil hasn’t burnt out. If there is no continuity, the valve won’t fire.

- Manual Override: Most high-quality Directional Control Valves have a manual override button. Press it—if the cylinder moves, the problem is electrical. If it doesn’t move, the valve spool is likely stuck due to contamination.

Preventive Maintenance Checklist

To keep your pneumatic system running at peak efficiency, follow this simple monthly routine:

Drain Water: Empty all manual drain valves and moisture separators.

Inspect FRLs: Clean filter elements and check lubricator levels.

Tighten Fittings: Thermal expansion can loosen pneumatic fittings over time.

Monitor Temperature: Excessive heat at the compressor or valves often signals a leak or friction issue.

Need High-Quality Replacement Parts?

At Mark & Aira Valve, we specialize in durable, high-performance pneumatic components designed for the toughest industrial environments. From heavy-duty pneumatic cylinders to precision FRL units and directional control valves, we provide the parts you need to eliminate downtime.

Frequently Asked Questions (FAQ)

Why is my pneumatic cylinder moving slowly or jerky?

Slow or erratic movement is usually caused by internal seal wear, insufficient lubrication, or a clogged air filter. If the seals are worn, air bypasses the piston, reducing force. Check your FRL unit to ensure it is providing clean, lubricated air at the correct pressure.

How do I find a hidden air leak in my pneumatic system?

The most effective way is the “Soap Water Test.” Apply soapy water to fittings, valves, and cylinder ports; if bubbles form, you’ve found your leak. For larger industrial systems, ultrasonic leak detectors can be used to hear high-frequency hissing that is otherwise inaudible.

What is an FRL unit, and does my system need one?

FRL stands for Filter, Regulator, and Lubricator. It is essential for any pneumatic system. The filter removes contaminants, the regulator maintains consistent pressure, and the lubricator adds a fine oil mist to reduce friction. Using a high-quality FRL unit can triple the lifespan of your solenoid valves and cylinders.

How can I tell if my solenoid valve has failed?

First, check the electrical coil for continuity with a multimeter. If the electrical side is fine, use the manual override button on the valve body. If the valve operates manually but not electronically, the coil is dead. If it won’t move at all, the internal spool is likely jammed by debris.

How often should I perform maintenance on a pneumatic system?

For standard industrial applications, a monthly inspection is recommended. This includes draining moisture from filters, checking lubricator oil levels, and inspecting fittings for leaks. Regular maintenance prevents 90% of sudden system failures.