Why Valve Procurement in Oil & Gas Requires More Than Just Price Comparison

Valve procurement in the oil and gas industry feels simple at first. You look at the price, a few specs, and a delivery date. But reality hits fast. A wrong valve can shut down a pipeline. It can jump the maintenance costs. It can trigger safety risks that nobody wants to deal with.

So, this cheat sheet keeps your buying decisions sharp. You get clear points on valve types, materials, standards, actuation, and the common mistakes many procurement teams repeat. If you deal with oil and gas valves, industrial valves, or you want the best valve for oil and gas pipelines, this guide walks you through the essentials without drowning you in jargon.

Understanding the Core Valve Types Used in Oil & Gas

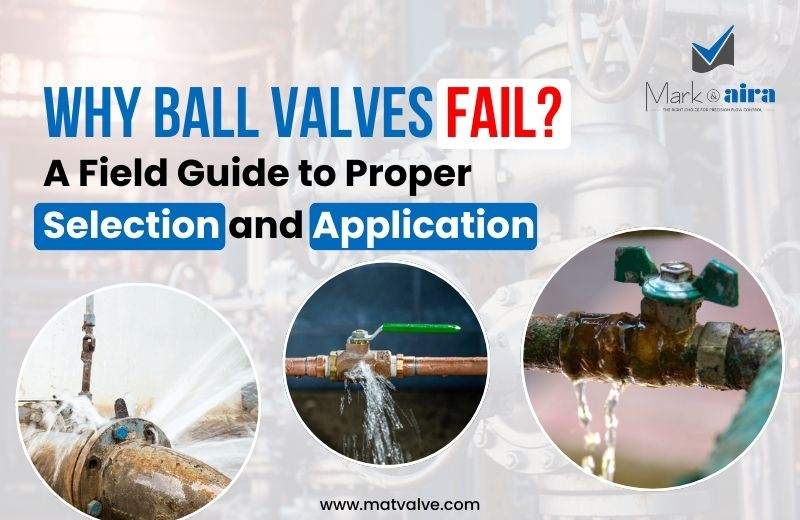

Ball Valves — When to Choose Them & Key Specifications

Ball valves stay popular because they give quick shutoff and low-pressure drop. You see them in pipeline isolation, compressor stations, and distribution networks. When you compare a ball valve vs butterfly valve for pipelines, ball valves win in tight sealing and high-pressure spots.

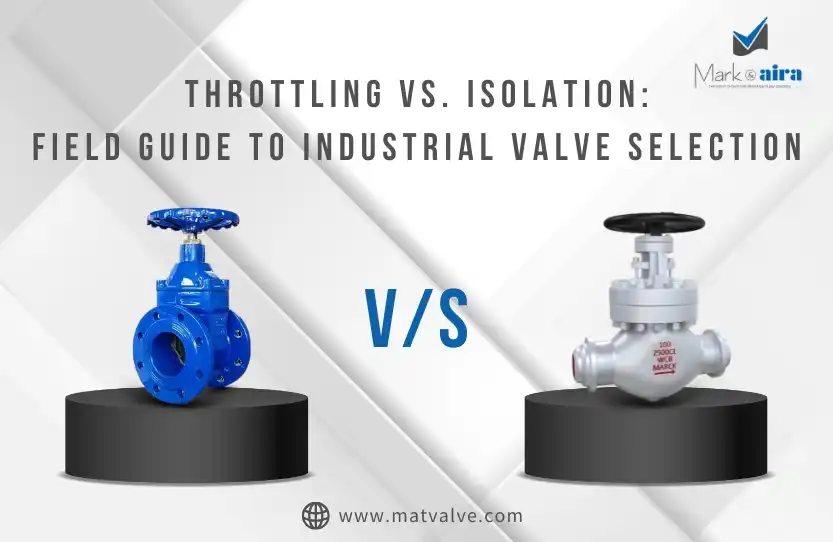

Gate Valves — Ideal for Pigging & Full-Bore Flow

Gate valves shine in pipeline work. The full-bore design allows pigging without issues. That alone makes buyers choose a gate valve over a ball valve in long-distance pipelines. When engineers search gate valve pipelines or gate valve vs ball valve, they want clarity.

Globe Valves — Precise Throttling & Flow Control

When you need control, not just on/off flow, globe valves do the job. Many plants use them for throttling or regulating across refining units. They handle pressure well, but they also create more pressure drop. Anyone searching for flow control valves usually looks for this balance. Check our Globe Valve range.

Check Valves — Preventing Backflow in High-Risk Lines

Check valves look simple, but they act like silent safety guards. Their job is to stop reverse flow, especially in high-pressure and hazardous lines. A failed check valve can push contaminated gas or liquid into the wrong area.

Butterfly Valves, Plug Valves & Specialty Valves

Butterfly valves and plug valves help when space becomes tight or when you want a lighter solution. They stay common in low-to-medium pressure lines. On the other side, safety valves and slam-shut valves for gas sit at the core of any emergency system. These specialty valves protect your installation when pressure spikes or something goes wrong.

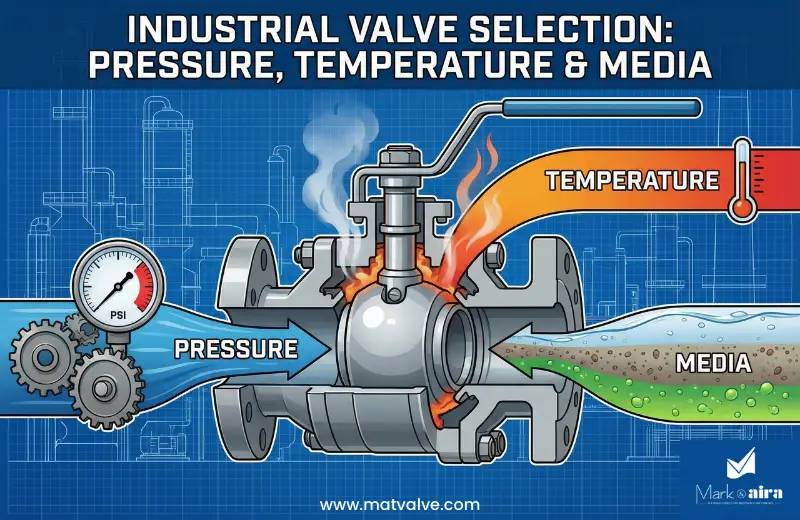

Valve Materials & Construction — The Most Overlooked Procurement Factor

Choosing the Right Material: Stainless, Cast, Forged, Duplex & Super-Duplex

Material selection decides the life of your valve. Many buyers underestimate this. Stainless steel works well for general applications, but cast or forged steel stands stronger for high-pressure gas. Offshore teams almost always lean toward duplex or super-duplex because of corrosion and seawater exposure. Searches like best valve material for seawater service duplex vs super duplex show how common this question is.

Matching Materials to Media: Sour Gas, Offshore, Slurry & Corrosive Environments

Each media type puts different stress on your valve. Sour gas eats weak alloys quickly. Slurry damages seats and internals. Corrosive chemicals punish poor material choices. This is where corrosion-resistant valves and high-pressure gas valves come into play. A simple mistake here leads to early failure. Many teams only look at specs, not the media details, and regret it later.

API & ASME Standards You Must Know Before Buying

Key Standards Simplified — API 6D, ASME B16.34, API 607 & More

Standards sound dry, but they protect you. API 6D covers pipeline valves. ASME B16.34 governs pressure-temperature ratings. API 607 focuses on fire-safe design. When you compare suppliers, check if they follow these. Buyers searching for API standards for valves or API 6D valve requirements want fast clarity without flipping through 200 pages of documents.

Procurments Also Read this Blog – Understanding API 6D, ISO, and CE Certifications for Valves in the UAE.

Certification & Testing — Hydrostatic, Leak, Fire-Safe, Pressure Rating

Every valve for oil and gas needs proper testing. Hydrostatic tests, leak tests, fire-safe verification, and MAWP checks show if the valve can survive real conditions. Many failed installations trace back to skipped or incomplete testing.

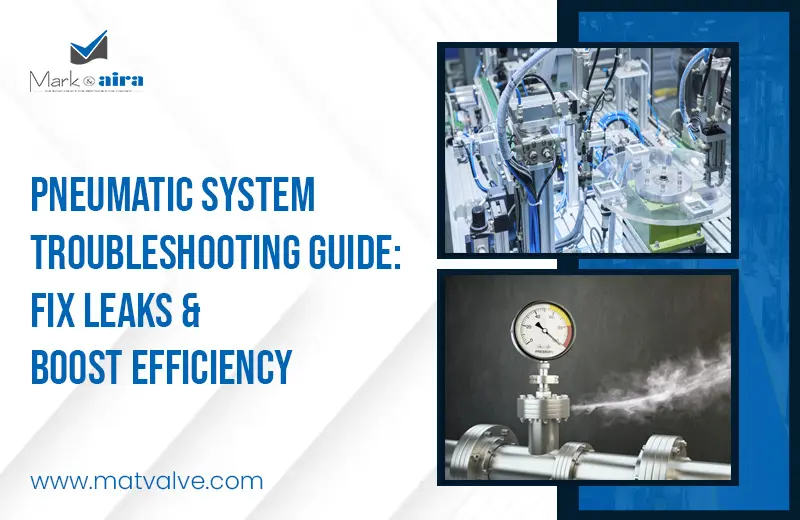

Manual vs Actuated Valves — What Procurement Teams Must Evaluate

Automation grows every year in this industry. Manual valves still work in many places, but operational safety demands automation in more sections of the plant.

Pneumatic, Electric & Hydraulic Actuators — Selection Guide

Actuators change the way operators control flow. Pneumatic actuators work well in remote or explosive environments. Electric actuators provide precise control. Hydraulic suits heavy-duty and high-pressure service. Engineers comparing valve actuator types or automated valve selection usually look for simple guidelines tied to real operations.

When to Retrofit vs Buy New — ROI Considerations

Sometimes you don’t need a new valve. You only need an actuator retrofit. Teams looking for actuator retrofit cost savings usually want to cut downtime and raise safety. A quick ROI check helps: compare cost of new purchase vs cost to assemble an actuator with existing valves. Retrofit usually saves money, as long as the valve body stays in good shape.

Application-Based Valve Selection Cheat Sheet

Upstream Applications — Drilling, Extraction & Wellhead

Upstream applications push valves into harsh conditions. High pressure, sand, corrosive media, and temperature swings hit them constantly. For high-pressure valves for upstream, buyers must look at strength, material grade, and ease of maintenance.

Midstream Applications — Pipelines, Pumping Stations & Terminals

Midstream stays all about movement and distance. Pipelines need pipeline valves with full-bore capability for pigging. Pumping stations need valves that can handle vibration and pressure surge.

Downstream Applications — Refining, Petrochemical & Processing Plants

Refineries need reliable control. Chemical plants push corrosive media that attack weak materials fast. Buyers search for refinery valves or process industry valves to narrow choices. Here, corrosion resistance and maintenance intervals matter more than price.

Procurement Red Flags — How to Avoid Expensive Mistakes

Mistake #1: Choosing Based Only on Cost

The cheapest valve often becomes the most expensive one later. Downtime, leaks, and repairs wipe out any savings. Procurement teams learn this lesson after a few painful experiences.

Mistake #2: Ignoring Standards, Testing & Certifications

Skipping standards invites trouble. If a valve lacks proper testing, it becomes a liability from day one. You can link back to your Certified Valves Page from here.

Mistake #3: Wrong Material vs Media Selection

Materials make or break the valve. When buyers skip corrosive media checks, failures hit early. Always match materials with your actual operating environment.

Mistake #4: Selecting Manual Valves Where Actuation Is Required

Some teams pick manual valves because they look cheaper. But operators struggle later with safety, control, and remote access. Actuation avoids most of these issues.

Mistake #5: Neglecting Maintenance & Spare Parts Compatibility

A valve without available spare parts becomes a nightmare. Some suppliers don’t keep steady inventories. Look for simple designs, compatible parts, and predictable maintenance schedules.

Quick Valve Procurement Checklist

Here’s the short version of what you need to review before buying:

- Correct valve type

- Right material

- Relevant API/ASME standards

- Full testing results

- Pressure rating and temperature range

- Manual or actuated

- Maintenance and spare parts availability

Engineers Also Showing Interest in this Blog – What UAE’s Elite Procurement Teams Really Look for in a Valve Supplier

Conclusion — Make Smarter, Safer & More Cost-Efficient Valve Procurement Decisions

Valve procurement in oil and gas demands more than skimming through a datasheet. The right valve protects your plant, reduces downtime, and keeps your operations safe. When you combine knowledge of valve types, materials, standards, actuation, and application-specific needs, you make better decisions every time.

Whether you handle oil and gas valve selection, or you need advice before buying valves for your next pipeline or processing plant, this cheat sheet sets the right foundation.

Need Expert Guidance on Selecting the Right Valve?

Get a free technical consultation or request a customized valve specification sheet for your project. Click here to talk to our engineering team.