Non-metallic valves solve a lot of problems—corrosion, contamination, heavy maintenance, chemical attack. Engineers trust them in water treatment, chemicals, pharma, irrigation, and dozens of other applications. But even the best polymer valve has limits. Some systems run too hot. Some lines face extreme pressure. Some processes demand mechanical strength that plastic simply can’t deliver.

I wrote this guide to help you understand those boundaries clearly. When you know where non-metallic valves fail, you choose smarter. You also avoid downtime, leakage, and expensive replacements.

For a full overview of valve materials, advantages, and industry use cases, you can refer to our Ultimate Guide to Non-Metallic Industrial Valves.

Temperature Limits of Polymer Valves

Temperature is the first property that decides if a plastic valve survives or fails. Every polymer has a thermal breaking point.

UPVC

UPVC starts softening when the temperature crosses ~60°C. Hot water lines or heated chemical processes push UPVC beyond safety limits.

CPVC

CPVC handles higher temperatures—around 90°C—but still not enough for steam or hot oil lines.

PP / PPH

PP works up to 80–90°C. Anything higher weakens the structure or causes deformation.

PVDF

PVDF stays strong up to ~120°C, but you still shouldn’t use it for steam, high-temperature condensate, or hot hydrocarbon transfer.

If your temperature goes beyond 120°C, non-metallic valves simply won’t survive. This is where metal valves, lined valves, or high-performance metal-to-metal ball valves come in.

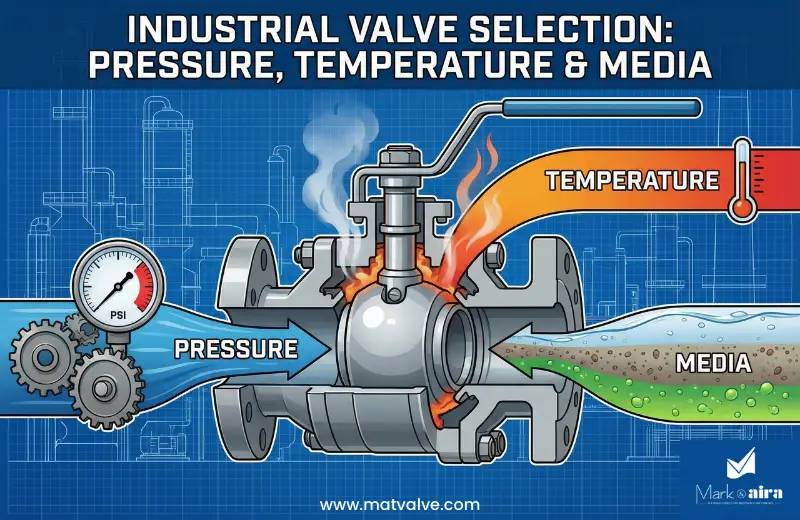

Pressure Limitations

Even the strongest non-metal valves—notably PVDF—cannot handle extreme pressure.

Where non-metal valves struggle:

- Boiler feed line

- High-pressure steam

- Compressed air above certain ratings

- Oil & gas pressure lines

- High-pressure pumping and injection system

Plastic walls expand slightly under load. Metal valves stay rigid. That’s why high-pressure segments in chemical plants and refineries never use non-metallic options.

For a deeper comparison of strength, you can revisit the Metallic vs Non-Metallic Valves section inside the pillar guide.

Mechanical Stress & Impact Weakness

Non-metallic valves stay strong in chemical environments, but they dislike mechanical abuse.

Weak areas include:

- High-vibration pipelines

- Hammering or rapid actuation

- Poorly supported lines

- Locations where valves take weight of heavy pipes

- Abrasive flow with solid particles

Steel tolerates bending and impact much better. Plastic works best only when pipelines stay aligned and stress-free.

If your plant has vibration-prone areas (like pump outlets), use metal or metal-lined valves.

Media Limitations

Most polymers resist acids and alkalis, but some media types can still attack them.

Avoid non-metallic valves when the media includes:

- Hot hydrocarbons

- Oils and solvents at elevated temperature

- High-abrasion slurry

- Bitumen, tar, molten materials

- Very aggressive solvents that permeate fluoropolymers

PP and PVDF resist many chemicals, but not everything. Some solvents slowly penetrate polymer walls and weaken them.

If you’re not sure, cross-check with a chemical compatibility chart or review the Material Selection Guide (UPVC vs CPVC vs PP vs PVDF).

When You MUST CHOOSE Metal or Lined Valves

Here are clear cases where metal always wins:

1. High-temperature operations

Steam, thermal oil, hot condensate, and heat transfer fluids exceed non-metal limits.

2. High-pressure industrial lines

Boiler lines, hydropower systems, pressure injection points, and oil & gas segments need metal.

3. Abrasive slurry and mining applications

Plastic scratches and wears out. Metal-lined valves or hardened metal ball valves perform better.

4. Hydrocarbon or solvent-heavy plants

High-temperature solvents degrade polymers faster.

5. Mechanical load areas

Valves installed close to pumps, heavy bends, or unsupported pipeline segments should not be plastic.

If your application matches any of these, explore metal valve category – High-Pressure Ball Valves.

Engineer’s Checklist

Before choosing a non-metal valve, check these points:

- Maximum temperature in the line

- Maximum pressure during peak operation

- Chemical compatibility of media

- Presence of abrasion

- Pipeline support and vibratio

- Need for purity vs mechanical strengt

- Expected valve lifecycle

- Actuator weight and torque

If more than two of these conditions exceed polymer limits, switch to metal or lined valves. It saves more money long-term than replacing a failed plastic valve later.

Final Recommendation

Non-metallic valves deliver excellent performance in water treatment, chemical dosing, pharmaceutical production, and many environmental applications. But they aren’t universal. Once the temperature, pressure, or mechanical stress crosses the material’s safe zone, you must choose metal-based solutions.

A smart selection prevents failure. If you want a complete understanding of materials, valve types, and industry mapping, refer to our Ultimate Guide to Non-Metallic Industrial Valves.

If you’re unsure whether your application needs non-metallic or metallic valves, contact our technical team.

We guide you on selecting the right valve material—UPVC, CPVC, PP, PVDF, metal, or lined—based on your actual operating conditions.

Explore our product categories or request expert assistance for your pipeline requirements.