In any industrial process, valves are the silent sentinels of safety and productivity. They do more than just start and stop flow; they manage the delicate balance of pressure, temperature, and velocity that keeps a facility operational.

The Stakes of Selection

For industries in the Middle East, valve selection is particularly critical due to extreme ambient temperatures (often exceeding 45°C) and high salinity in coastal areas. Common challenges include:

- Safety Risks: Incorrectly specified valves can lead to “water hammer,” cavitation, or catastrophic leaks.

- Efficiency Losses: Improperly sized valves cause excessive pressure drops, leading to higher energy consumption in pump and compressor systems.

- Costly Downtime: Using a standard valve in a corrosive desalination environment can lead to failure within months rather than years.

This guide provides a roadmap for navigating the complex world of industrial valves, ensuring your selection aligns with both international standards (API, ASME) and the unique environmental demands of the UAE.

Classification of Industrial Valves

Before choosing a specific model, it is essential to categorize valves by their primary intent:

- Isolation (On/Off): Designed to be either fully open or fully closed (e.g., Gate and Ball valves).

- Regulation (Throttling): Used to control the flow rate at various points between open and closed (e.g., Globe and Butterfly valves).

- Non-Return (Check): Automatically prevent backflow to protect sensitive equipment like pumps.

The “STAMPED” Rule: A helpful industry mnemonic for selection is STAMPED: Size, Temperature, Application, Media (fluid type), Pressure, Ends (connections), and Delivery.

Major Types of Industrial Valves & Their Applications

Ball Valves

Ball valves use a rotating sphere with a hole to control flow.

- Operation: Quarter-turn (90°).

- Best For: Tight shut-off in gas and liquid lines.

- UAE Application: Widely used in oil and gas upstream facilities due to their reliable sealing and quick operation.

Gate Valves

Designed for isolation, gate valves move a “gate” up and down to open or close the path.

- Strength: Offers a straight-through flow with minimal pressure drop.

- Best For: High-pressure, high-temperature isolation where throttling is NOT required.

- UAE Application: Main steam lines in power generation and heavy-duty pipelines.

Butterfly Valves

These use a rotating disk to regulate flow.

- Strength: Lightweight, compact, and cost-effective for large-diameter pipes.

- Best For: Water distribution and low-pressure cooling systems.

- UAE Application: Standard in desalination plants and HVAC systems for high-rise developments.

Globe Valves

Globe valves feature a spherical body and a plug that moves vertically to regulate flow.

- Strength: Precise throttling and frequent operation.

- Best For: Controlling flow where a pressure drop is acceptable.

- UAE Application: Chemical processing and fuel oil systems where precise volume control is mandatory.

Plug Valves

Similar to ball valves but uses a tapered or cylindrical “plug.”

- Strength: Simple design, high durability in dirty environments.

- Best For: Slurry and viscous media.

- UAE Application: Wastewater treatment and petrochemical refineries handling heavy crudes.

Diaphragm Valves

Uses a flexible diaphragm to seal the flow path.

- Strength: The fluid never touches the valve stem, preventing contamination.

- Best For: Corrosive or hygienic media.

- UAE Application: Pharmaceutical manufacturing and food/beverage industries in Dubai Industrial City.

Solenoid Valves

Electromechanically operated valves used for automated control.

- Strength: Extremely fast response times.

- Best For: Safety shut-off systems and pilot control.

- UAE Application: Integrated into Emergency Shutdown (ESD) systems across ADNOC and DEWA facilities.

Manual Valves vs. Actuated Valves

| Feature | Manual Valves | Actuated (Pneumatic/Electric) |

|---|---|---|

| Control | Human intervention (Handwheels/Levers) | Remote, automated control via PLC/DCS |

| Speed | Slow, dependent on operator | Instantaneous or precisely timed |

| Cost | Low initial investment | Higher (requires power/air & sensors) |

| Best Use | Maintenance isolation, non-critical lines | Critical process control, hazardous areas |

In the UAE, the shift toward Smart Valves (actuators with IIoT sensors) is accelerating as plants look to reduce labor costs and improve predictive maintenance.

How to Select the Right Industrial Valve

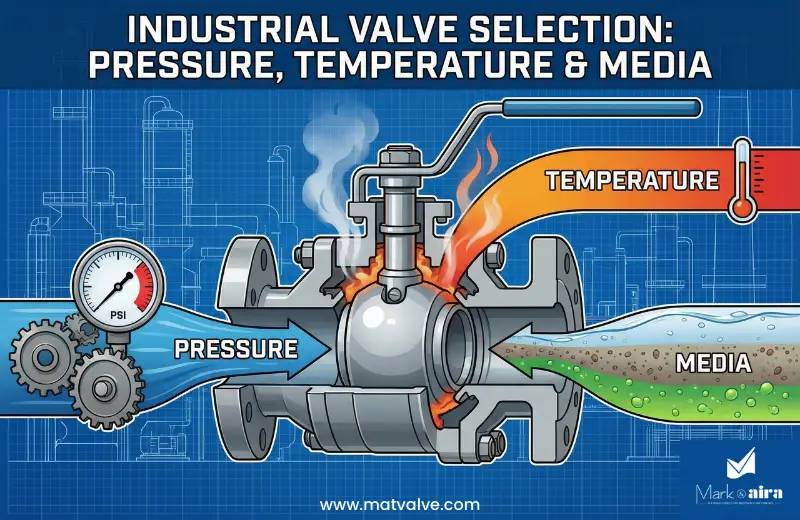

To ensure longevity in the Middle East, evaluate these three pillars:

- Pressure & Temperature: Verify the PN (Pressure Nominal) rating. Remember that as temperature increases, the allowable working pressure of the material (e.g., Stainless Steel vs. Cast Iron) decreases.

- Process Media: Is the fluid abrasive (sand-laden oil), corrosive (seawater), or viscous (slurry)? This dictates whether you need Duplex Stainless Steel, PTFE lining, or Stellite-faced trims.

- Industry Specifics:

- Marine/Offshore: Requires high corrosion resistance (Monel or Hastelloy).

- Water/Utilities: Focuses on cost-efficiency and large-diameter butterfly valves.

Common Valve Selection Mistakes

- Oversizing: A common error in control valves. An oversized valve operates nearly closed, leading to “hunting,” seat erosion, and poor control.

- Ignoring Material Compatibility: Using standard carbon steel in high-salinity coastal areas leads to rapid external corrosion.

- Neglecting Maintainability: Selecting a “disposable” valve might save money today, but a valve with replaceable seats and seals reduces the Total Cost of Ownership (TCO).

How Mark & Aira Valves Supports the UAE Industry

As a specialized supplier & stockist based in the UAE, Mark & Aira Valve bridges the gap between high-end manufacturing and local project needs.

- Local Inventory: We maintain a massive stock of ball, butterfly, and solenoid valves in Dubai to prevent project delays.

- Technical Guidance: Our engineers provide application-specific consultation to ensure your valves meet API 6D and other critical certifications.

- Customization: We offer pneumatic and electric actuation assembly locally, providing fast turnaround for automated valve requirements.

Choosing the right valve is an investment in your plant’s safety and profitability. Whether it’s a simple manual gate valve for isolation or a high-precision actuated control valve, understanding the nuances of each type is the first step toward operational excellence.

Ready to specify valves for your next project?

Explore our industrial Valves in the UAE or contact us today for a technical consultation.