In the chemical processing sector, accuracy and reliability are prime factors. Many engineers and plant managers often underestimate the important role of the diaphragm valve. When handling corrosive media or aggressive acids, the wrong valve choice can lead to serious issues, including leaks, contamination, costly downtime, and even safety hazards. That’s where diaphragm valves come into action.

Designed to perform under challenging environments, these corrosion-resistant valves are engineered to isolate fluids and prevent contact with metallic parts, ensuring process integrity and extended service life. Whether in acid transfer lines, pharmaceutical mixing units, or chemical dosing systems, diaphragm valves quietly uphold operational efficiency and plant safety.

In this blog, we uncover the lesser-known aspects of diaphragm valve chemical applications and why industries across the globe, especially in the UAE’s chemical sector, rely on them as indispensable industrial diaphragm valves for long-term, acid-resistant performance.

What Makes Diaphragm Valves Unique?

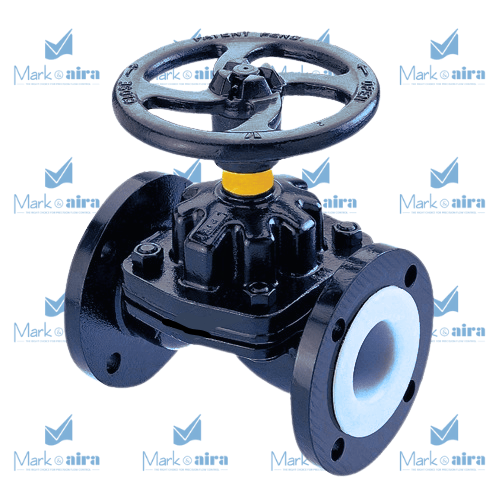

Unlike conventional valves that rely on metal-to-metal contact, diaphragm valves operate using a flexible diaphragm that completely isolates the process media from internal components. This simple but brilliant design prevents corrosion, contamination, and leakage, offering advantages for handling aggressive or toxic chemicals. The diaphragm acts as a responsive barrier, ensuring precise flow control without exposing the valve body or stem to corrosive media.

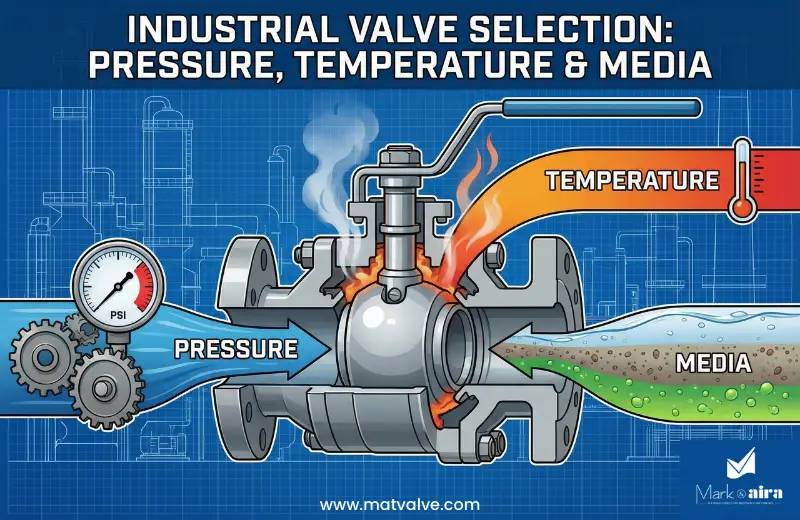

Compared to ball, globe, or gate valves, industrial diaphragm valves offer superior sealing integrity and require less maintenance, making them ideal for chemical plant valves where cleanliness and safety are paramount. They are available mainly in two diaphragm valve types: weir-type (for throttling control) and straight-through type (for viscous or slurry fluids).

Their adaptability extends further with material options like FEP/PFA-lined diaphragm valves and rubber-lined diaphragm valves, which resist acids and solvents. This design versatility and corrosion resistance make diaphragm valves an essential component in the UAE’s chemical industries, where performance and reliability define operational success.

Fact 1: Corrosion Resistance Is Just the Beginning

When it comes to chemical handling, a corrosion-resistant diaphragm valve is more than just a safeguard; it’s a long-term investment in plant operation. By incorporating advanced materials like PTFE, rubber, and elastomer linings, these valves provide outstanding resistance to strong acids, alkalis, and aggressive solvents. This internal protection ensures that neither the valve body nor the stem is exposed to corrosive elements, dramatically extending service life and minimizing unplanned maintenance. In high-risk applications involving hydrochloric acid (HCl), sulfuric acid (H₂SO₄), or caustic soda, these acid-resistant valves UAE facilities rely on are designed to perform flawlessly under harsh conditions. Their chemical compatibility, especially in PTFE-lined valve UAE operations, helps maintain process purity while reducing downtime. This blend of durability, chemical resistance, and consistent sealing integrity makes diaphragm valves one of the most durable industrial valves in chemical process systems.

Fact 2: Diaphragm Valves Provide Leak-Free Operation

One of the standout features of a leak-proof diaphragm valve is its ability to create a complete seal between the process media and mechanical components. The flexible sealed diaphragm valve design ensures zero contact between the fluid and the valve’s moving parts, eliminating wear, corrosion, and potential leakage paths.

This diaphragm valve not only increases operational efficiency but also prevents fugitive emissions that can harm workers and the environment. For chemical plants handling volatile or toxic substances, chemical safe valves UAE industries prefer diaphragm valves as a proactive measure for meeting stringent environmental and safety regulations.

By minimizing leaks and emissions, these emission-free valves UAE industries deploy play a vital role in achieving sustainability goals and compliance with safety standards. Whether in acid dosing systems or solvent handling applications, diaphragm valves provide the confidence that every chemical handling valve should complete containment, every time.

Fact 3: Low Maintenance, High Reliability

In the demanding chemical sector, simplicity often translates to reliability, and that’s exactly what a low-maintenance diaphragm valve is known for. With minimal moving parts and a straightforward sealing mechanism, wear and tear are drastically reduced. Unlike traditional valves that rely on multiple contact surfaces and packing glands, diaphragm valves maintain performance without frequent lubrication or seal replacement.

This design advantage makes them exceptionally reliable for continuous operations involving corrosive or abrasive fluids. Over time, their long-life industrial valves UAE users depend on to provide consistent performance with minimal downtime, ensure smoother plant operations.

For chemical processors seeking cost efficiency, diaphragm valves offer more than durability; they deliver a lower total cost of ownership. Their robust build and simple maintenance make them truly maintenance-free valves, ideal for chemical process valves where durability, safety, and economy are paramount. It’s a long-term solution designed for durable valves UAE industries that demand uninterrupted performance.

Also Read: Mitigating Supply Chain Risk: Why Local Stock and Certified Valve Manufacturing Matter in the UAE

Fact 4: Versatile Across Chemical & Acid Applications

A true hallmark of the chemical process diaphragm valve is its unmatched versatility across multiple industries. Designed to handle slurries, viscous fluids, and corrosive liquids, these valves maintain precise flow control even in the most challenging media conditions. Whether used for concentrated acids, abrasive slurries, or high-viscosity polymers, diaphragm valves perform with consistent accuracy and safety.

Their compatibility with various actuation methods: manual, pneumatic, or electric, allows seamless integration into process automation valve systems, giving operators flexibility and control. In the UAE’s chemical and acid plants, they have become a standard for reliability and operational efficiency.

Beyond chemical processing, diaphragm valves find wide use in pharmaceutical manufacturing, water treatment, and mining industries, where clean, leak-proof operation is essential. This adaptability sticks to their reputation as one of the most trusted industrial valves UAE industries depend on, especially for demanding acid handling valve UAE operations requiring long-term durability and precision.

Fact 5: Trusted Choice in UAE & Middle East Industries

Across the UAE and GCC, chemical engineers depend on diaphragm valves for their proven reliability and compatibility with international standards. Leading Pharma Diaphragm Valve UAE suppliers deliver products that meet ISO, API, and CE certifications, ensuring the highest safety and performance benchmarks for industrial operations.

These valves are integral to chemical plants, desalination projects, and refineries, where precision and durability are vital. Supported by a strong network of chemical valve distributors across the UAE, local industries enjoy faster access to products, on-site technical support, and reliable after-sales service, minimizing downtime and enhancing productivity.

Whether for new installations or replacement needs, Middle East diaphragm valves have become synonymous with quality and trust. Their adaptability and proven track record make them the preferred chemical plant valve partner for industries across the region, reflecting the UAE’s growing commitment to safe, sustainable, and globally compliant UAE industrial valve solutions.

Conclusion

With their superior corrosion resistance, leak-proof reliability, low maintenance needs, and versatile performance, backed by strong trust across industries, diaphragm valves have become essential for chemical and process plants.. For engineers and managers seeking long-term reliability, these valves provide a perfect balance of performance, safety, and cost efficiency.

Whether you need acid valve solutions for aggressive media or reliable flow control in automated systems, partnering with a reputed chemical valve supplier UAE ensures the best value and after-sales support. Looking to buy diaphragm valves UAE industries rely on? Connect with us as a trusted industrial diaphragm valve partner today. Contact Mark & Aira team for the right diaphragm valve solutions for your application.