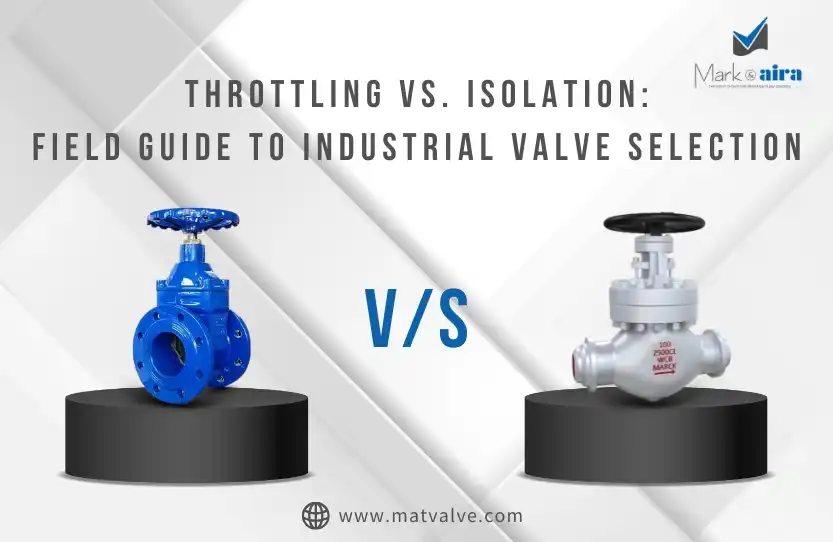

Globe Valves or Gate Valves: When to Use Which

In the world of industrial piping, picking between a globe valve and a gate valve is one of those decisions that seems small until you’re staring at a vibrating pipe or a leaking seal. Both are heavy hitters in the UAE’s oil, gas, and water sectors, but they are built for entirely different jobs.

If you use a gate valve where a globe valve should be, you’ll ruin the seat in weeks. If you swap a globe for a gate on a high-volume line, you’ll choke your flow and waste energy. Understanding the “why” behind their design is the only way to keep your system running without constant intervention.

How Gate Valves Work

Think of a gate valve like a sliding door or a guillotine. It has a flat or wedge-shaped gate that moves up and down. When the valve is open, the gate is fully withdrawn from the flow path. This is its biggest strength: the fluid moves in a straight line with almost zero resistance.

Because the gate is either “all in” or “all out,” these are strictly isolation valves. They aren’t meant for quick operation. You have to turn the handwheel multiple times to move that gate. This slow movement is actually a safety feature in large pipelines because it prevents the dreaded water hammer that happens when you stop a massive volume of fluid too fast.

How Globe Valves Work

A globe valve is a different beast entirely. Instead of a sliding gate, it uses a plug (or disc) that moves vertically against a stationary ring seat. The name comes from the old globular body shape, though modern ones don’t always look like spheres.

The key here is the flow path. Inside a globe valve, the fluid has to make two 90-degree turns—it goes up, over a wall, and back down. This “S” shape creates a lot of resistance, but it also gives the operator incredible control. By moving the plug closer to or further from the seat, you can precisely dictate how much fluid gets through.

Performance Comparison: The "Big Three"

When you’re choosing between the two, you have to look at how they handle flow, pressure, and the “stop” factor.

1. Flow Control (Throttling)

- Globe Valves:

This is where they shine. If you need to regulate pressure or volume—say, keeping a tank at exactly 50%—the globe valve is your tool. The design allows for “fine-tuning” without the valve vibrating itself to pieces.

- Gate Valves:

Never, ever use a gate valve for throttling. If you leave a gate valve 20% open, the high-velocity fluid will hit the bottom of the gate, causing it to vibrate. This “chatter” will eventually destroy the seats and the gate itself.

2. Pressure Drop

- Gate Valves:

Very low pressure drop. Since the flow path is straight and unobstructed, the downstream pressure is nearly the same as the upstream pressure. This makes them perfect for long-distance transport lines.

- Globe Valves:

High pressure drop. Because the fluid has to navigate that internal “S” curve, you lose energy. If your system is already running at a low pressure, a globe valve might “choke” the line too much.

3. Shut-off Capability

- Gate Valves:

They offer a decent seal, but because they rely on a sliding motion, any debris in the line can get trapped in the bottom groove (the “seat”), preventing a tight close.

- Globe Valves:

Generally offer superior shut-off. Since the plug is pressed directly down onto the seat (like a bottle stopper), it can achieve a very tight, “bubble-tight” seal even in high-pressure steam services.

Application-Based Selection

So, where do we actually see these in the field?

Use a Gate Valve when:

- You need to move massive amounts of fluid over long distances.

- The valve will stay open (or closed) 99% of the time.

- You want to minimize pumping costs (less resistance = less power).

Typical in: Crude oil pipelines, main water headers, and sewage systems.

Use a Globe Valve when:

- You need to frequently adjust the flow rate.

- You are dealing with high-temperature steam or cooling water.

- Pressure drop isn’t a dealbreaker, but precision is.

- Typical in: Boiler feed lines, fuel oil systems, and chemical sampling lines.

Cost & Maintenance Comparison

From a budget perspective, gate valves are usually cheaper to buy upfront, especially in larger sizes. They have a simpler design and fewer internal parts that wear out from friction.

However, globe valves are often easier to maintain. Because the seat and plug are more accessible, you can often “lap” or repair the sealing surfaces without cutting the entire valve out of the line. Gate valves, once the internal guides or seats are heavily scarred by debris, often have to be replaced entirely.

Another factor is the stem. Gate valves often have “rising stems” which require a lot of vertical clearance. If you are working in a tight space, like an offshore platform or a compact pump skid, you might have to opt for a globe valve or a non-rising stem gate valve just to make it fit.

Final Recommendation

The choice usually boils down to one question: Are you stopping the flow or managing it?

If your goal is to isolate a section of a 24-inch pipe for maintenance once a year, go with a gate valve. It’s cost-effective and won’t hinder your flow during normal operation.

If you are trying to control the temperature of a heat exchanger by varying the water flow, go with a globe valve. It’s the only one of the two designed to handle the stress of being partially open.

At Mark & Aira Valves, we see a lot of “improper swaps” in the field—usually people trying to save a bit of money by using a gate valve for a job it wasn’t built for. Don’t make that mistake. It always costs more in the long run when you have to shut down the line for an unscheduled repair.

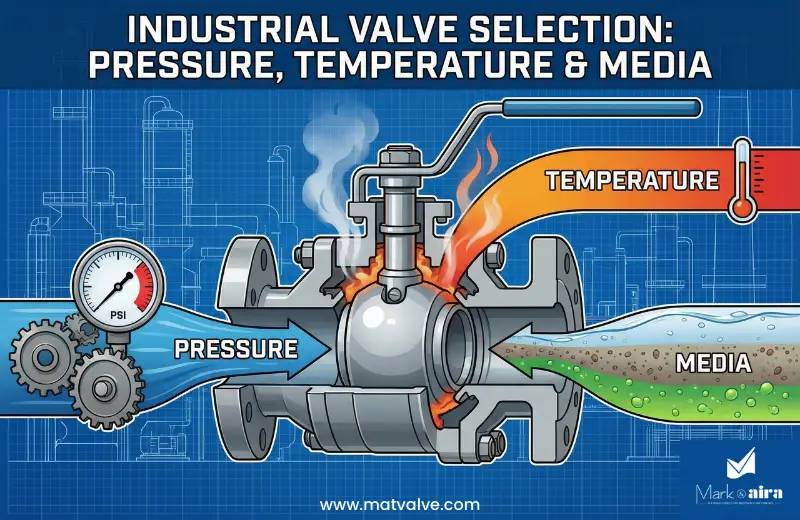

Still not sure which one fits your P&ID? Check out our industrial valve selection guide to look at pressure and temperature ratings, or contact our UAE technical team for a direct recommendation on your specific project.