Valve Trim FAQs: Essential Answers for Engineers and Buyers

Introduction to Valve Trim FAQs

Welcome to our valve trim FAQs guide. Whether you’re a seasoned engineer, a purchasing agent, or someone new to valve systems, this blog will help you understand the essentials of valve trim. Here, we answer the most common questions related to valve trim FAQs, API 600 trim numbers, galling issues, flow positions, and valve type differences.

What Is Valve Trim in an Industrial Valve?

Valve Trim FAQs: Understanding the Basics

Valve trim refers to all the internal parts of a valve that come in contact with the process fluid, such as the disc, seat, stem, backseat, and sleeves. These components control the flow, sealing, and operation of the valve. Learn more about our valves.

What Are API 600 Trim Numbers and What Do They Mean?

Valve Trim FAQs: API 600 Numbering Explained

API 600 assigns trim numbers (1 to 18) to standard combinations of materials used in valve internals using which, manufacturers design each trim for specific conditions like temperature, corrosion, and pressure. For example, Trim 5 uses Stellite and is great for erosive service, while Trim 9 (Monel) is ideal for seawater.

What Are the Most Common API Trim Numbers?

Common API trims include:

| Trim No. | Disc/Seat Material | Stem Material | Applications |

|---|---|---|---|

| 1 | 13% Cr Steel | 13% Cr Steel | General service, mild corrosion |

| 5 | Hard-faced (Stellite) | 13% Cr Steel | Abrasive, high-pressure service |

| 9 | Monel | Monel | Corrosive media (seawater, etc.) |

| 10 | 316 Stainless Steel | 316 Stainless Steel | Highly corrosive applications |

| 12 | 316 SS (Hard-faced) | 316 Stainless Steel | Corrosive + abrasion resistance |

| 13 | Alloy 20 | Alloy 20 | Sulphuric acid resistance |

✅ Note: Always match the trim with fluid compatibility and temperature limits.

Which Valve Trim Is Best for Corrosive Fluids?

Industries commonly use trims like Trim 9 (Monel), Trim 10 (316 SS), and Trim 13 (Alloy 20) for corrosive environments as they offer excellent resistance to acids, seawater, and other aggressive fluids. Explore corrosion-resistant valves here.

What Is the Difference Between Trim 5 and Trim 8 in Valves?

Both use Stellite hard-facing however, engineers typically use Trim 5 in gate valves and high-pressure conditions, while they prefer Trim 8 for globe valves and moderate pressures. Both these effectively prevent wear and galling.

What Causes Galling in Valve Components?

Galling occurs when similar metals rub against each other under pressure and stick together, damaging the surface. Stainless steel trims like 316 SS often experience this when manufacturers don’t apply hard-facing.

How Can Galling Be Prevented in Gate and Globe Valves?

You can avoid galling by:

- Using dissimilar materials

- Adding Stellite or Ni-Cr hard-facing

- Applying lubricants or coatings

For example, Trim 12 (316 SS with Stellite) is a good choice to prevent galling.

What Is the Purpose of Stellite Hard-Facing in Valve Trims?

Stellite is a hard, wear-resistant alloy used to coat the seat or disc, in order to protect against erosion, corrosion, and galling. Therefore, manufacturers commonly use it in trims 5, 8, 11, and 12.

Which Trim Should Be Used for Seawater or Brine Applications?

Because of its high resistance to salt and chlorides, engineers widely use Trim 9 (Monel) for such applications. Consequently, it’s ideal for marine and offshore valves.

What Materials Are Used in Valve Trim 1, Trim 5, and Trim 9?

- Trim 1: 410 SS for stem, disc, and seat – basic trim for non-corrosive service.

- Trim 5: 410 SS stem with Stellite-faced disc and seat – wear-resistant.

- Trim 9: Monel for all parts – for corrosive, salt-rich environments.

What Is the Best Trim Material for High-Temperature Services?

Trim 3 (F310 SS) and Trim 17 (347 SS with Stellite) are excellent for high-temperature operations as they offer strength and resistance up to 593°C or more.

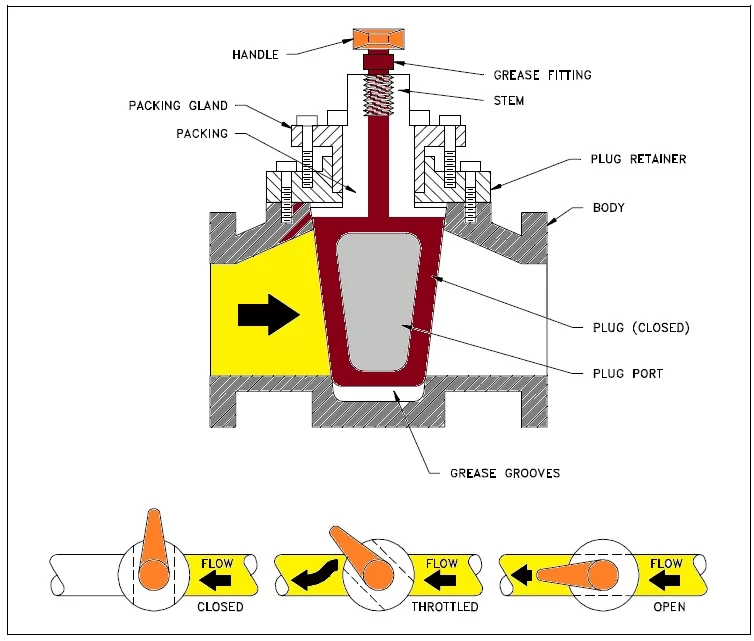

Do Ball Valves Have Trims Like Globe or Gate Valves?

Yes, but the concept is slightly different in ball valves, where the trim refers to the ball, stem, and seats. While soft-seated balls (like PTFE) are good for clean services, metal-seated options handle abrasives or high temperature. Check out our ball valve range.

How Are Valve Trims Selected Based on Service Conditions?

Valve trim selection depends on:

- Fluid type (clean, corrosive, erosive)

- Pressure & temperature

- Throttling or on/off service

Using the wrong trim can lead to leakage, erosion, or early failure.

What Is the Function of Hard-Facing in Valve Seats?

Hard-facing, like Stellite, increases the wear resistance of valve seats hence, it’s essential in high-pressure and erosive conditions. As a result, it ensures a tight seal and long service life.

Are Trims Different for Gate, Globe, Ball, and Check Valves?

Yes, trims vary based on valve type:

- Globe valves often need erosion-resistant trims for throttling.

- Gate valves need trims that prevent galling and ensure full open/close sealing.

- Ball valves focus on stem sealing and ball-seat compatibility.

- Check valves require durable discs and seats for sealing under backflow.

What Are the Disadvantages of Using the Wrong Valve Trim?

Using incorrect trims can cause:

- Galling or erosion

- Seal failure

- Reduced valve lifespan

- Increased maintenance

Therefore, choosing the right trim boosts performance and safety and that’s why let us help you select the right trim.

What Does Trim 13 (Alloy 20) Offer for Chemical Industries?

Alloy 20 offers outstanding resistance to sulfuric acid and other aggressive chemicals hence it’s ideal for chemical processing, acid handling, and dye plants.

How to Select Valve Trim for Erosive Services?

For erosive media (slurries, steam with debris), use trims with Stellite or Ni-Cr hard-facing, like Trim 5, 8, or 14 as these materials resist pitting and mechanical wear.

Can You Use Stainless Steel Trims for Throttling Service?

Not all stainless steel trims are good for throttling like for example, soft stainless trims (like 316 SS) can gall or erode. On the other hand, trims with Stellite-faced seats and discs are better for throttling.

Still Have Questions About Valve Trim FAQs?

Our technical team is happy to help hence, feel free to contact us now or explore our full product catalog.